Surface Treatment

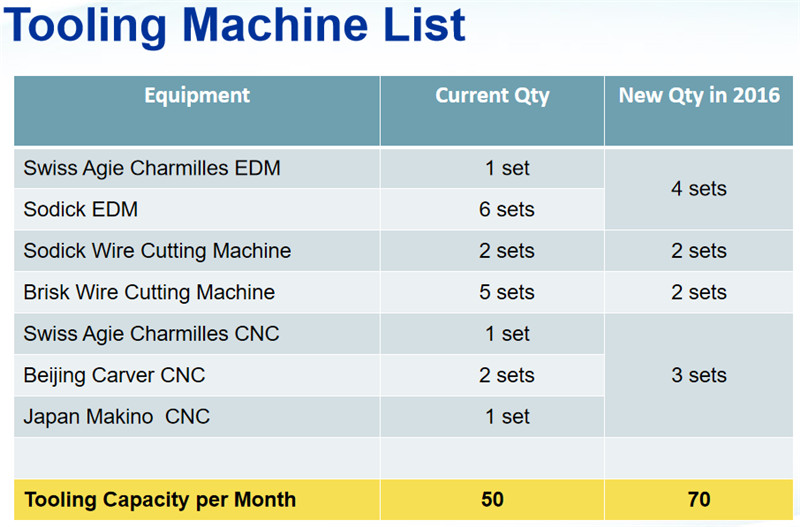

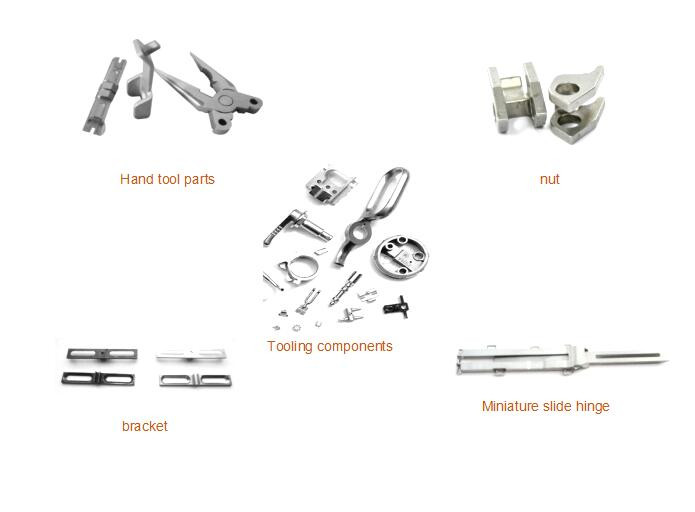

1.Heat Treatment 2.Magnetic grinding 3.Plane grinding 4.Passivation 5.Electro-polish,hand polish 6.PVD 7.Sand blasting 8.Brush 9.Laser engraving 10.Silk Print 11.PaintingMachining

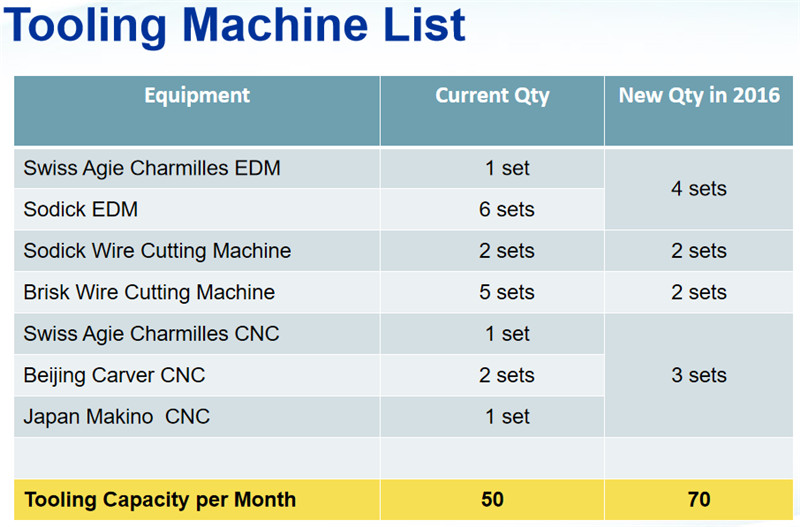

1.CNC turning and milling 2.Centerless,ID and OD grinding. 3.Fine hole drilling,reaming and burnishing. 4.Precision honing 5.Thread rolling and cutting 6.Laser welding,cutting and drilling 1. What is MIM technology?Features

Metal Injection Molding technology as a high-quality precision components near net shape technology, has the advantages conventional powder metallurgy, precision machining and casting methods can not acquire. • As same as the production of plastics production complex shape of small metal parts (0.1-100g); • MIM Parts properties of homogeneous, high dimensional accuracy and high relative density (≥ 95%); • Good surface smoothness; • Product quality stability, high efficiency, easy to achieve high-volume, large-scale production.MIM Material

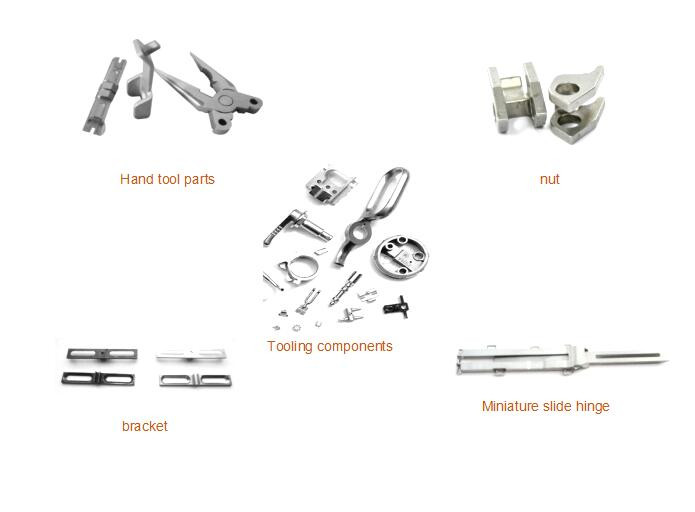

Fe-based alloy steel, stainless steel, nickel-based alloys, tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy, fine ceramics, etc.. Fe-2Ni, Fe-8Ni; 316L,17-4PH ;WC-Co; Al2O3, ZrO, SiO2; W-Ni-Fe, W-Ni-Cu, W-Cu; Ti,Ti-6Al-4V; Fe, Fe14Nd2B, SmCo5 Ningbo Jiehuang Electirc Tech Co.,Ltd, We are experts in metal parts such as forging parts, casting parts, metal stamping parts, CNC machining parts, powder metal parts, metal injection molding (MIM) parts, plastic injection parts, sanitary valves, various hardware products and so on. We serve a diverse range of applications in diverse industries – Automotive, Industrial, Electronics and Medical. Our factory loacted in Cidong Industrial Zone,Cixi, Ningbo City. Now we have 16 pieces Injection molding machines, 4 pieces Degreasing furnace and 6 pieces sintering furnace. 8 engineers, 50+ workers, advanced testing equipment, perfect management system and more than 10 years of work experience allow us to serve many top companies around the world. MIM technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and Other industrial parts. Looking forward to growing together with you!

Ningbo Jiehuang Electirc Tech Co.,Ltd, We are experts in metal parts such as forging parts, casting parts, metal stamping parts, CNC machining parts, powder metal parts, metal injection molding (MIM) parts, plastic injection parts, sanitary valves, various hardware products and so on. We serve a diverse range of applications in diverse industries – Automotive, Industrial, Electronics and Medical. Our factory loacted in Cidong Industrial Zone,Cixi, Ningbo City. Now we have 16 pieces Injection molding machines, 4 pieces Degreasing furnace and 6 pieces sintering furnace. 8 engineers, 50+ workers, advanced testing equipment, perfect management system and more than 10 years of work experience allow us to serve many top companies around the world. MIM technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and Other industrial parts. Looking forward to growing together with you! We will work with you through all phases of project development – from requirement planning, tooling design and mass production, to FOT and manufacturing, through to the shipping . We can make any precision metal products, such as metal auto parts, electronic parts, 3C electronic parts, precision medical parts!Through more than 10 years of operation and deep cultivation in the technical field, Company has more than 50+ workers, has 15 production lines with an annual production capacity of over 75 million. The company has passed ISO9001 quality management system, ISO14001 environmental management system and OHSAS18001 occupational health and safety management system certification; The company’s technological innovation has obtained 14 invention patents, 13 utility model patents, 3 scientific and technological achievements, 2 municipal high-tech products, and more than 30 MIM key common technology research results, all of which have achieved industrial application. .It has a registered capital of 33.5 million yuan and is a professional provider of metal injection molding (MIM) technology solutions. Service provider, a high-tech enterprise integrating R&D, production and sales. The company's proprietary technology belongs to the new materials and high-end equipment fields that the state is currently supporting. The technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and iND. Industrial parts.

We will work with you through all phases of project development – from requirement planning, tooling design and mass production, to FOT and manufacturing, through to the shipping . We can make any precision metal products, such as metal auto parts, electronic parts, 3C electronic parts, precision medical parts!Through more than 10 years of operation and deep cultivation in the technical field, Company has more than 50+ workers, has 15 production lines with an annual production capacity of over 75 million. The company has passed ISO9001 quality management system, ISO14001 environmental management system and OHSAS18001 occupational health and safety management system certification; The company’s technological innovation has obtained 14 invention patents, 13 utility model patents, 3 scientific and technological achievements, 2 municipal high-tech products, and more than 30 MIM key common technology research results, all of which have achieved industrial application. .It has a registered capital of 33.5 million yuan and is a professional provider of metal injection molding (MIM) technology solutions. Service provider, a high-tech enterprise integrating R&D, production and sales. The company's proprietary technology belongs to the new materials and high-end equipment fields that the state is currently supporting. The technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and iND. Industrial parts.

One-stop Metal parts supplier in ChinaOur core manufacturing equipment is imported directly from Germany.We have 15 engineers in our R&D centre, all of them are doctors or professors from University of Science and Technology of China.Strict Quality Control, Rigorous product inspection after mass productionOn 2017, we sent a international bussiness dep. in Ningbo, –Ningbo Jiehuang Chiyang Electric Tech Co.,Ltd. to deal with all our international bussiness.Our group has been chosen as the preferred supplier by lots of well-known companies for its custom metal products with competitive price, stable performance and high technology.We sincerely want to be your good business partner for a long time in China. If you have any enquiry for quotation, please contact us freely. Your OEM metal parts are welcome. Our efficient and friendly sales team will always offer you very competitive quotations and a fast response to all your enquiries.

One-stop Metal parts supplier in ChinaOur core manufacturing equipment is imported directly from Germany.We have 15 engineers in our R&D centre, all of them are doctors or professors from University of Science and Technology of China.Strict Quality Control, Rigorous product inspection after mass productionOn 2017, we sent a international bussiness dep. in Ningbo, –Ningbo Jiehuang Chiyang Electric Tech Co.,Ltd. to deal with all our international bussiness.Our group has been chosen as the preferred supplier by lots of well-known companies for its custom metal products with competitive price, stable performance and high technology.We sincerely want to be your good business partner for a long time in China. If you have any enquiry for quotation, please contact us freely. Your OEM metal parts are welcome. Our efficient and friendly sales team will always offer you very competitive quotations and a fast response to all your enquiries.

Features

Metal Injection Molding technology as a high-quality precision components near net shape technology, has the advantages conventional powder metallurgy, precision machining and casting methods can not acquire. • As same as the production of plastics production complex shape of small metal parts (0.1-100g); • MIM Parts properties of homogeneous, high dimensional accuracy and high relative density (≥ 95%); • Good surface smoothness; • Product quality stability, high efficiency, easy to achieve high-volume, large-scale production.MIM Material

Fe-based alloy steel, stainless steel, nickel-based alloys, tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy, fine ceramics, etc.. Fe-2Ni, Fe-8Ni; 316L,17-4PH ;WC-Co; Al2O3, ZrO, SiO2; W-Ni-Fe, W-Ni-Cu, W-Cu; Ti,Ti-6Al-4V; Fe, Fe14Nd2B, SmCo5 Ningbo Jiehuang Electirc Tech Co.,Ltd, We are experts in metal parts such as forging parts, casting parts, metal stamping parts, CNC machining parts, powder metal parts, metal injection molding (MIM) parts, plastic injection parts, sanitary valves, various hardware products and so on. We serve a diverse range of applications in diverse industries – Automotive, Industrial, Electronics and Medical. Our factory loacted in Cidong Industrial Zone,Cixi, Ningbo City. Now we have 16 pieces Injection molding machines, 4 pieces Degreasing furnace and 6 pieces sintering furnace. 8 engineers, 50+ workers, advanced testing equipment, perfect management system and more than 10 years of work experience allow us to serve many top companies around the world. MIM technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and Other industrial parts. Looking forward to growing together with you!

Ningbo Jiehuang Electirc Tech Co.,Ltd, We are experts in metal parts such as forging parts, casting parts, metal stamping parts, CNC machining parts, powder metal parts, metal injection molding (MIM) parts, plastic injection parts, sanitary valves, various hardware products and so on. We serve a diverse range of applications in diverse industries – Automotive, Industrial, Electronics and Medical. Our factory loacted in Cidong Industrial Zone,Cixi, Ningbo City. Now we have 16 pieces Injection molding machines, 4 pieces Degreasing furnace and 6 pieces sintering furnace. 8 engineers, 50+ workers, advanced testing equipment, perfect management system and more than 10 years of work experience allow us to serve many top companies around the world. MIM technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and Other industrial parts. Looking forward to growing together with you! We will work with you through all phases of project development – from requirement planning, tooling design and mass production, to FOT and manufacturing, through to the shipping . We can make any precision metal products, such as metal auto parts, electronic parts, 3C electronic parts, precision medical parts!Through more than 10 years of operation and deep cultivation in the technical field, Company has more than 50+ workers, has 15 production lines with an annual production capacity of over 75 million. The company has passed ISO9001 quality management system, ISO14001 environmental management system and OHSAS18001 occupational health and safety management system certification; The company’s technological innovation has obtained 14 invention patents, 13 utility model patents, 3 scientific and technological achievements, 2 municipal high-tech products, and more than 30 MIM key common technology research results, all of which have achieved industrial application. .It has a registered capital of 33.5 million yuan and is a professional provider of metal injection molding (MIM) technology solutions. Service provider, a high-tech enterprise integrating R&D, production and sales. The company's proprietary technology belongs to the new materials and high-end equipment fields that the state is currently supporting. The technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and iND. Industrial parts.

We will work with you through all phases of project development – from requirement planning, tooling design and mass production, to FOT and manufacturing, through to the shipping . We can make any precision metal products, such as metal auto parts, electronic parts, 3C electronic parts, precision medical parts!Through more than 10 years of operation and deep cultivation in the technical field, Company has more than 50+ workers, has 15 production lines with an annual production capacity of over 75 million. The company has passed ISO9001 quality management system, ISO14001 environmental management system and OHSAS18001 occupational health and safety management system certification; The company’s technological innovation has obtained 14 invention patents, 13 utility model patents, 3 scientific and technological achievements, 2 municipal high-tech products, and more than 30 MIM key common technology research results, all of which have achieved industrial application. .It has a registered capital of 33.5 million yuan and is a professional provider of metal injection molding (MIM) technology solutions. Service provider, a high-tech enterprise integrating R&D, production and sales. The company's proprietary technology belongs to the new materials and high-end equipment fields that the state is currently supporting. The technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and iND. Industrial parts.

One-stop Metal parts supplier in ChinaOur core manufacturing equipment is imported directly from Germany.We have 15 engineers in our R&D centre, all of them are doctors or professors from University of Science and Technology of China.Strict Quality Control, Rigorous product inspection after mass productionOn 2017, we sent a international bussiness dep. in Ningbo, –Ningbo Jiehuang Chiyang Electric Tech Co.,Ltd. to deal with all our international bussiness.Our group has been chosen as the preferred supplier by lots of well-known companies for its custom metal products with competitive price, stable performance and high technology.We sincerely want to be your good business partner for a long time in China. If you have any enquiry for quotation, please contact us freely. Your OEM metal parts are welcome. Our efficient and friendly sales team will always offer you very competitive quotations and a fast response to all your enquiries.

One-stop Metal parts supplier in ChinaOur core manufacturing equipment is imported directly from Germany.We have 15 engineers in our R&D centre, all of them are doctors or professors from University of Science and Technology of China.Strict Quality Control, Rigorous product inspection after mass productionOn 2017, we sent a international bussiness dep. in Ningbo, –Ningbo Jiehuang Chiyang Electric Tech Co.,Ltd. to deal with all our international bussiness.Our group has been chosen as the preferred supplier by lots of well-known companies for its custom metal products with competitive price, stable performance and high technology.We sincerely want to be your good business partner for a long time in China. If you have any enquiry for quotation, please contact us freely. Your OEM metal parts are welcome. Our efficient and friendly sales team will always offer you very competitive quotations and a fast response to all your enquiries.

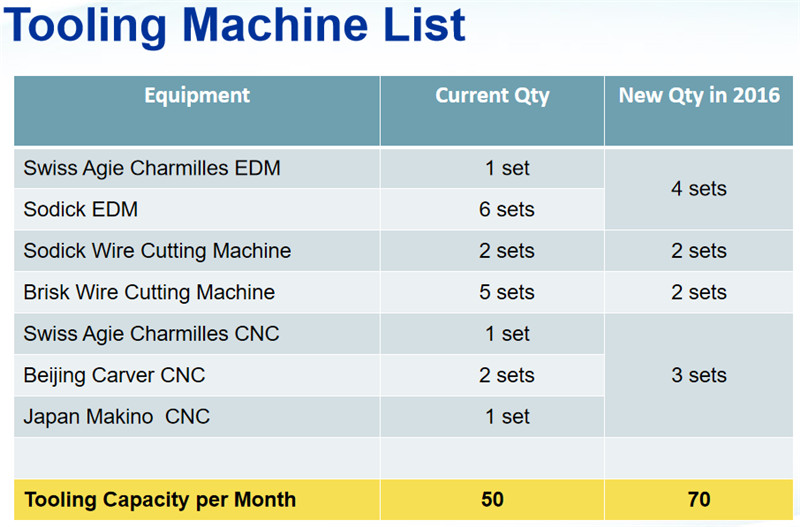

Features

Metal Injection Molding technology as a high-quality precision components near net shape technology, has the advantages conventional powder metallurgy, precision machining and casting methods can not acquire. • As same as the production of plastics production complex shape of small metal parts (0.1-100g); • MIM Parts properties of homogeneous, high dimensional accuracy and high relative density (≥ 95%); • Good surface smoothness; • Product quality stability, high efficiency, easy to achieve high-volume, large-scale production.MIM Material

Fe-based alloy steel, stainless steel, nickel-based alloys, tungsten alloy, carbide, titanium, magnetic materials, Kovar alloy, fine ceramics, etc.. Fe-2Ni, Fe-8Ni; 316L,17-4PH ;WC-Co; Al2O3, ZrO, SiO2; W-Ni-Fe, W-Ni-Cu, W-Cu; Ti,Ti-6Al-4V; Fe, Fe14Nd2B, SmCo5 Ningbo Jiehuang Electirc Tech Co.,Ltd, We are experts in metal parts such as forging parts, casting parts, metal stamping parts, CNC machining parts, powder metal parts, metal injection molding (MIM) parts, plastic injection parts, sanitary valves, various hardware products and so on. We serve a diverse range of applications in diverse industries – Automotive, Industrial, Electronics and Medical. Our factory loacted in Cidong Industrial Zone,Cixi, Ningbo City. Now we have 16 pieces Injection molding machines, 4 pieces Degreasing furnace and 6 pieces sintering furnace. 8 engineers, 50+ workers, advanced testing equipment, perfect management system and more than 10 years of work experience allow us to serve many top companies around the world. MIM technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and Other industrial parts. Looking forward to growing together with you!

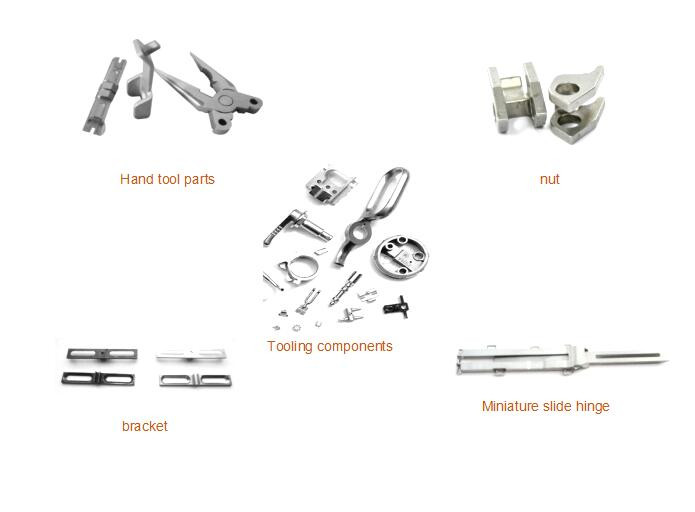

Ningbo Jiehuang Electirc Tech Co.,Ltd, We are experts in metal parts such as forging parts, casting parts, metal stamping parts, CNC machining parts, powder metal parts, metal injection molding (MIM) parts, plastic injection parts, sanitary valves, various hardware products and so on. We serve a diverse range of applications in diverse industries – Automotive, Industrial, Electronics and Medical. Our factory loacted in Cidong Industrial Zone,Cixi, Ningbo City. Now we have 16 pieces Injection molding machines, 4 pieces Degreasing furnace and 6 pieces sintering furnace. 8 engineers, 50+ workers, advanced testing equipment, perfect management system and more than 10 years of work experience allow us to serve many top companies around the world. MIM technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and Other industrial parts. Looking forward to growing together with you! We will work with you through all phases of project development – from requirement planning, tooling design and mass production, to FOT and manufacturing, through to the shipping . We can make any precision metal products, such as metal auto parts, electronic parts, 3C electronic parts, precision medical parts!Through more than 10 years of operation and deep cultivation in the technical field, Company has more than 50+ workers, has 15 production lines with an annual production capacity of over 75 million. The company has passed ISO9001 quality management system, ISO14001 environmental management system and OHSAS18001 occupational health and safety management system certification; The company’s technological innovation has obtained 14 invention patents, 13 utility model patents, 3 scientific and technological achievements, 2 municipal high-tech products, and more than 30 MIM key common technology research results, all of which have achieved industrial application. .It has a registered capital of 33.5 million yuan and is a professional provider of metal injection molding (MIM) technology solutions. Service provider, a high-tech enterprise integrating R&D, production and sales. The company's proprietary technology belongs to the new materials and high-end equipment fields that the state is currently supporting. The technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and iND. Industrial parts.

We will work with you through all phases of project development – from requirement planning, tooling design and mass production, to FOT and manufacturing, through to the shipping . We can make any precision metal products, such as metal auto parts, electronic parts, 3C electronic parts, precision medical parts!Through more than 10 years of operation and deep cultivation in the technical field, Company has more than 50+ workers, has 15 production lines with an annual production capacity of over 75 million. The company has passed ISO9001 quality management system, ISO14001 environmental management system and OHSAS18001 occupational health and safety management system certification; The company’s technological innovation has obtained 14 invention patents, 13 utility model patents, 3 scientific and technological achievements, 2 municipal high-tech products, and more than 30 MIM key common technology research results, all of which have achieved industrial application. .It has a registered capital of 33.5 million yuan and is a professional provider of metal injection molding (MIM) technology solutions. Service provider, a high-tech enterprise integrating R&D, production and sales. The company's proprietary technology belongs to the new materials and high-end equipment fields that the state is currently supporting. The technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and iND. Industrial parts.

One-stop Metal parts supplier in ChinaOur core manufacturing equipment is imported directly from Germany.We have 15 engineers in our R&D centre, all of them are doctors or professors from University of Science and Technology of China.Strict Quality Control, Rigorous product inspection after mass productionOn 2017, we sent a international bussiness dep. in Ningbo, –Ningbo Jiehuang Chiyang Electric Tech Co.,Ltd. to deal with all our international bussiness.Our group has been chosen as the preferred supplier by lots of well-known companies for its custom metal products with competitive price, stable performance and high technology.We sincerely want to be your good business partner for a long time in China. If you have any enquiry for quotation, please contact us freely. Your OEM metal parts are welcome. Our efficient and friendly sales team will always offer you very competitive quotations and a fast response to all your enquiries.

One-stop Metal parts supplier in ChinaOur core manufacturing equipment is imported directly from Germany.We have 15 engineers in our R&D centre, all of them are doctors or professors from University of Science and Technology of China.Strict Quality Control, Rigorous product inspection after mass productionOn 2017, we sent a international bussiness dep. in Ningbo, –Ningbo Jiehuang Chiyang Electric Tech Co.,Ltd. to deal with all our international bussiness.Our group has been chosen as the preferred supplier by lots of well-known companies for its custom metal products with competitive price, stable performance and high technology.We sincerely want to be your good business partner for a long time in China. If you have any enquiry for quotation, please contact us freely. Your OEM metal parts are welcome. Our efficient and friendly sales team will always offer you very competitive quotations and a fast response to all your enquiries.