JieHuang is specialized in pressure die casting process and aluminum/zinc metal castings production for more than 15 years, we are capable to provide complex OEM die casting parts for your specific applications and purposes. A thorough understanding of die casting techniques enables us to create cost-effective die casting products with the best performance and exact dimensions to meet your request, premium quality and competitive prices will make your stand out in local market. We’ll apply advanced machinery and systems to alleviate risk during the process. Lightweight yet strong aluminum or different zinc materials are available for selection, such as A360, A380, ADC2, etc. Several parts can be cast into a single unit, which simplifies the supply chain. DiecastingMould provides one-stop service for the OEM clients, our custom die casting parts market including door locks, automotive, heavy equipment, lightning, electrical cable clamps, vehicle, and more industries and fields. Whether you require a new product design or OEM die castings of finished design, welcome to get in touch with us, a free quote will be sent back within 24 hours. Mold design and mold making for OEM parts, as well as surface finishing services, are offered for your requirements.

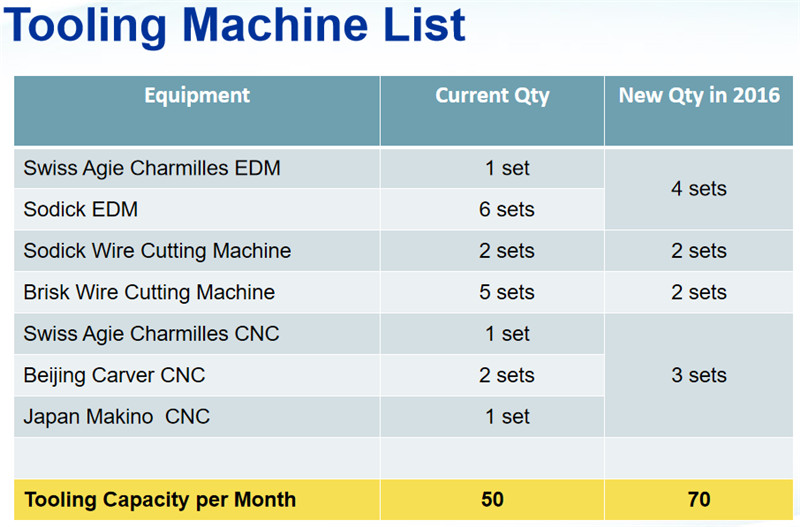

FACTORY&EQUIPMENT

DIE CASTING PARTS

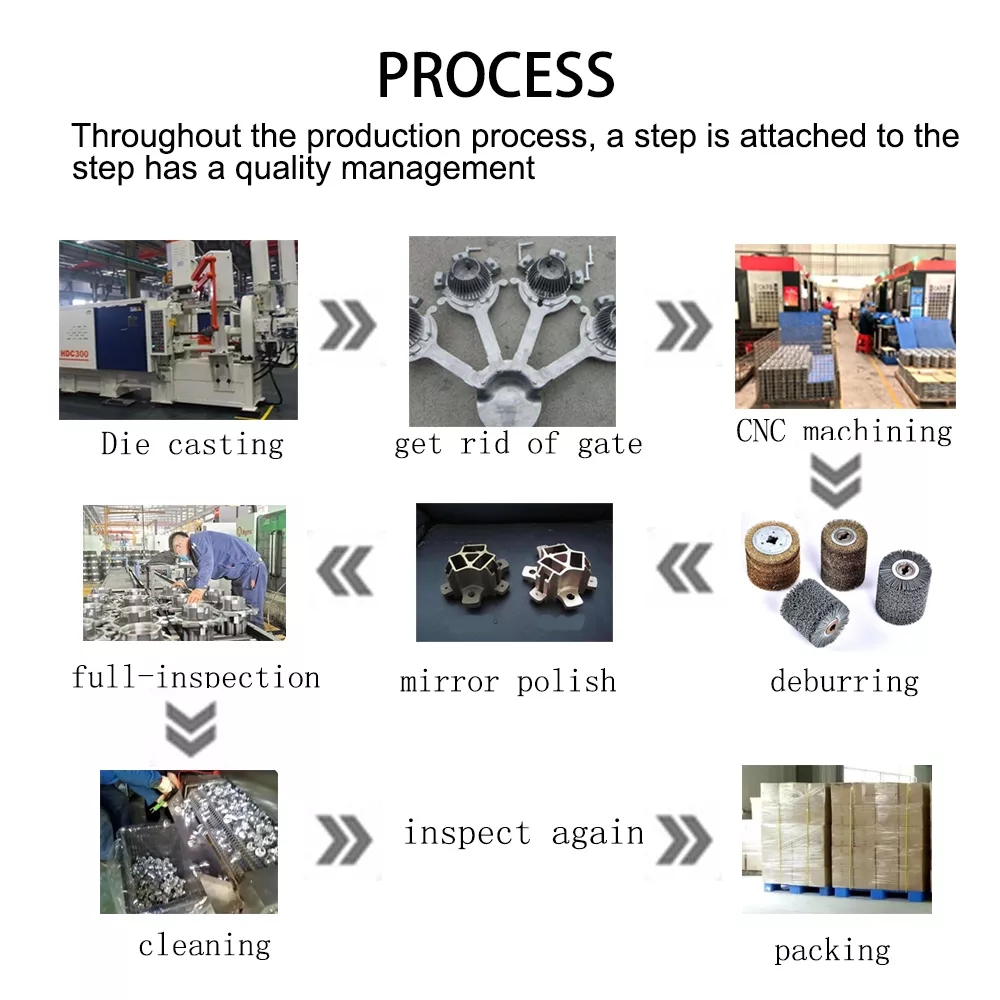

DIE CASTING PROCESS&PACKING

FAQ

1.Are you a manufacturer or a trading company?

We are a professional manufacturer with over 15 years’ export experience for designing and producing vehicle machinery parts.

2. Can you make casting according to our drawing?

Yes, we can make casting according to your drawing, 2D drawing, or 3D cad model. If the 3D cad model can be supplied, the development of the tooling can be more efficient. But without 3D, based on 2D drawing we can still make the samples properly approved.

3.How can I get some samples?

If you need, we are glad to offer you samples for free, but the new clients are expected to pay the courier cost, and the charge will be deducted from the payment for formal order.

4.Can you make casting based on our samples?

Yes, we can make measurement based on your samples to make drawings for tooling making.

5.What’s your quality control device in house?

We have spectrometer in house to monitor the chemical property, tensile test machine to control the mechanical property and UT Sonic as NDT checking method to control the casting detect under the surface of casting.

One-stop Metal parts supplier in ChinaOur core manufacturing equipment is imported directly from Germany.We have 15 engineers in our R&D centre, all of them are doctors or professors from University of Science and Technology of China.Strict Quality Control, Rigorous product inspection after mass production