Ningbo Jiehuang Electronic Technology Co., Ltd., a leading one-stop metal parts supplier in China, has recently announced the addition of a new service to meet the growing demand for fully dense ceramic parts made using injection moulding technology. The company, with its team of experienced professionals, can now support the development of complex, tight-tolerance ceramic components from prototype through to full volume production.

Injection moulding technology has revolutionized the way products are manufactured in many industries. It involves the use of fine ceramic powders compounded with thermoplastic binders to produce a homogeneous pelletized feedstock. The feedstock is then injected into a cavity mould to form net-shaped parts with high precision and minimal waste. The resulting ceramic parts are then thermally treated to remove the binder and sintered at high temperatures to obtain fully dense ceramic parts.

One of the advantages of injection moulding is its ability to produce high-volume production of complex parts with tight tolerances. This makes it ideal for industries such as electronics, automotive, aerospace, and medical, where the demand for high-performance parts with precise dimensions is crucial.

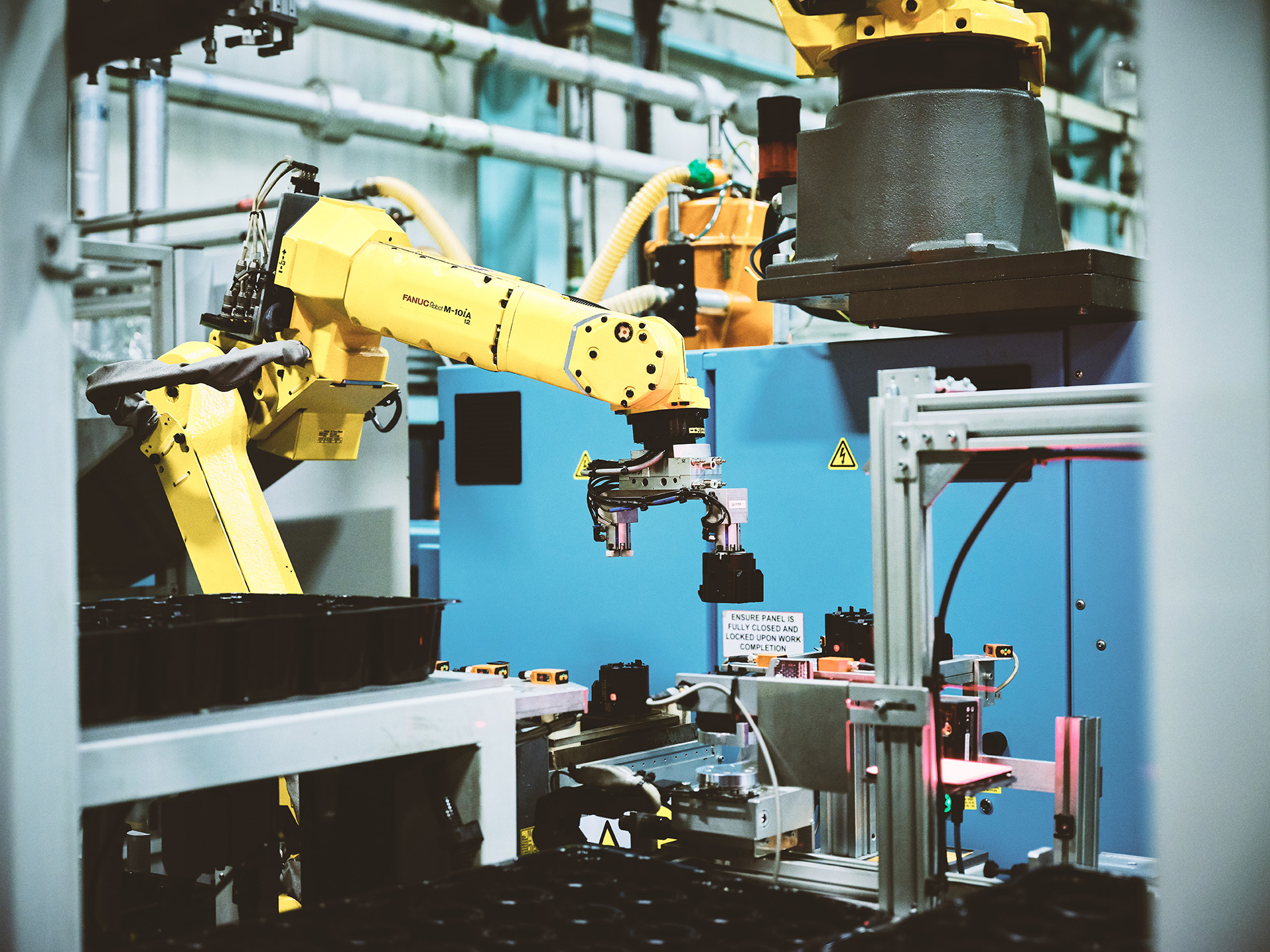

At Ningbo Jiehuang Electronic Technology, the injection moulding process is carried out using state-of-the-art equipment and under the supervision of trained professionals. The company's expertise in developing custom metal parts, such as forging parts, casting parts, metal stamping parts, CNC machining parts, powder metal parts, and metal injection moulding (MIM) parts, ensures that clients receive the best-in-class service for their ceramic component needs.

"We are excited to add injection moulding technology to our list of services," said a spokesperson for Ningbo Jiehuang Electronic Technology Co., Ltd. "We have seen an increasing demand for fully dense ceramic parts in various industries, and we believe that our expertise in metal parts can be applied to ceramic parts as well. Our team is dedicated to providing the best possible service to our clients, and we are confident that our injection moulding service will meet their expectations."

Ningbo Jiehuang Electronic Technology Co., Ltd., with its commitment to quality and customer satisfaction, has established itself as a reliable partner for companies looking for a one-stop solution for their metal part needs. With the addition of injection moulding technology, the company has expanded its capabilities and is well positioned to cater to the evolving needs of the market.

In conclusion, the addition of injection moulding technology to Ningbo Jiehuang Electronic Technology Co., Ltd.'s services is a significant development that underscores the company's commitment to providing the best possible service to its clients. With its expertise in metal parts and injection moulding technology, the company is well positioned to meet the growing demand for fully dense ceramic parts in various industries.