Ningbo Jiehuang Electronic Technology Co., Ltd. is one of the leading one-stop metal parts suppliers in China, offering a variety of services to clients worldwide. With a team of experts who have many years of experience in developing custom metal parts, the company has gained a reputation for producing high-quality products that meet their clients’ unique needs.

One of their core competencies is the production of metal parts using the Metal Injection Molding (MIM) process. MIM is a manufacturing technique that allows for the production of parts with complex shapes and geometries, making it a popular choice for industries such as aerospace, automotive, medical, and defense.

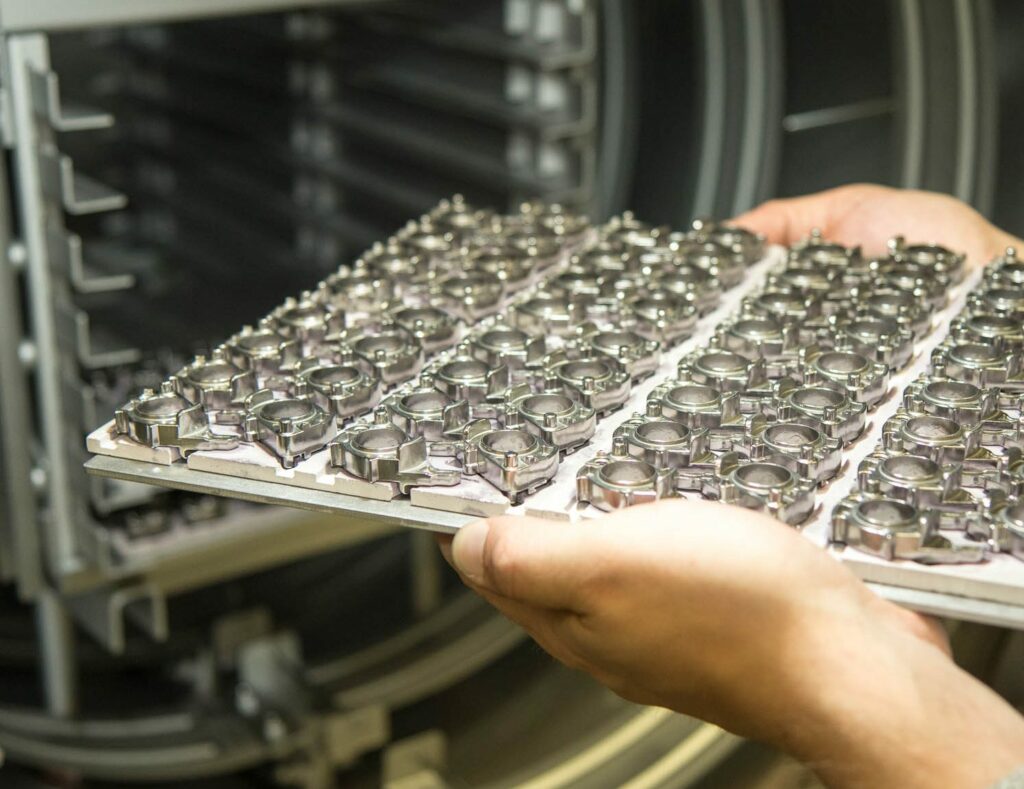

In traditional metal shaping, the design options can be limited by the manufacturing process, but with MIM, the possibilities are endless. The MIM process involves mixing metal powder with a binder material to create a “feedstock,” which is then injected into a mold cavity. The binder is then removed through a process called “debinding,” and the resulting part is sintered at high temperatures to produce a solid metal component.

MIM offers unparalleled design freedom, allowing for the production of parts with features such as thin walls, undercuts, and complex internal geometry. This level of complexity is difficult, if not impossible, to achieve with traditional manufacturing techniques. MIM is also a cost-effective option, particularly for high-volume production runs, as it allows for the creation of parts with minimal material waste.

Ningbo Jiehuang Electronic Technology Co., Ltd. offers a wide range of MIM parts, from small and intricate components to larger and more complex industrial parts. Their MIM parts have superior mechanical properties and accuracy, making them ideal for a variety of applications.

In addition to MIM, the company also offers other metal part production techniques, such as forging, casting, metal stamping, CNC machining, and powder metal. This one-stop-shop approach allows them to provide clients with a comprehensive solution to their metal parts needs.

The company’s commitment to quality is evident in their use of state-of-the-art equipment and technologies. They have invested heavily in the latest machinery and inspection equipment to ensure that their products meet the highest standards of quality and integrity.

Ningbo Jiehuang Electronic Technology Co., Ltd. is dedicated to providing their clients with exceptional service and support throughout the entire production process. From the initial concept design to final delivery, they work closely with their clients to ensure that their needs are met and their expectations are exceeded.

In conclusion, Ningbo Jiehuang Electronic Technology Co., Ltd. is a valuable partner for businesses in need of custom metal parts. Their expertise in Metal Injection Molding and other metal production techniques, combined with their commitment to quality and customer service, make them a trusted provider of metal parts in China and beyond.