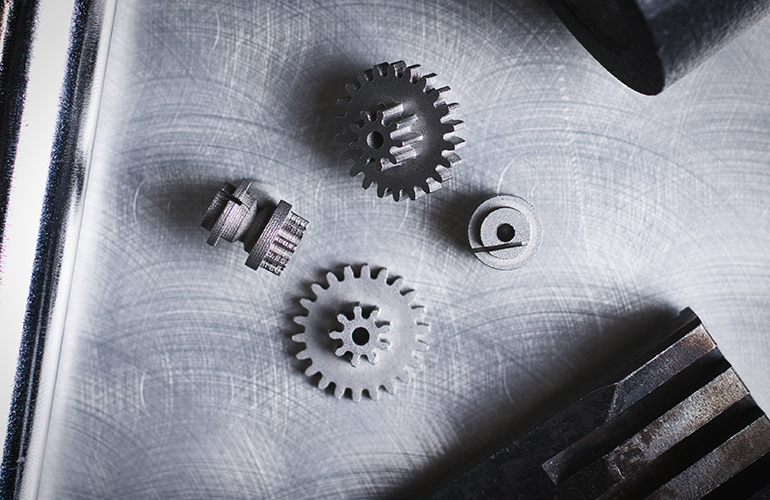

Metal injection molding is a process that combines the benefits of plastic injection molding with the superior properties of metal. The process involves the mixing of metal powders with a thermoplastic or wax binder to form a feedstock. This feedstock is then injected into a mold cavity using the same type of machinery used in plastic injection molding. Once the mold is filled, the part is allowed to cool and solidify. The final product is a highly uniform, dense, and highly precise metal part with excellent mechanical properties.

The MIM process can produce metal parts with complex geometries, thin walls, high dimensional accuracy, and excellent surface finish. It is ideal for producing small to medium-sized parts with intricately designed features that are difficult or impossible to achieve using traditional manufacturing methods. The MIM process can produce parts made from a variety of metals such as stainless steel, titanium, copper, brass, and others.

Ningbo Jiehuang Electronic Technology Co., Ltd. offers MIM services to cater to the needs of various industries such as automotive, aerospace, healthcare, and electronics, among others. The use of MIM technology in these industries is increasing, and the demand for high-quality, complex metal parts is growing rapidly. MIM is an excellent alternative to traditional manufacturing methods such as casting and machining, which may be time-consuming and expensive.

The MIM process is highly efficient, as it can produce many parts in a single cycle. It also offers a high level of repeatability, as the process is highly automated, and the parts produced are highly uniform. The use of MIM technology can save manufacturers time and money by reducing production time, minimizing material waste, and eliminating the need for extensive post-processing.

Ningbo Jiehuang Electronic Technology Co., Ltd. has a team of highly skilled engineers and technicians who take pride in delivering high-quality products to their clients. The company's commitment to quality is reflected in their use of state-of-the-art MIM equipment and strict quality control measures. They ensure that every part produced meets the client's specifications and requirements, and they are always striving to improve and innovate their processes.

At Ningbo Jiehuang Electronic Technology Co., Ltd., they understand the importance of customer service and satisfaction. They work closely with their clients to understand their needs and requirements, and they offer customized solutions tailored to meet their specific needs. Their experienced team of engineers and technicians can provide technical support and guidance throughout each stage of the MIM process to ensure that the final product meets the client's expectations.

In conclusion, Ningbo Jiehuang Electronic Technology Co., Ltd. is a leading one-stop metal parts supplier in China with years of experience in developing custom metal parts using various manufacturing methods. Their use of MIM technology has expanded the possibilities for producing high-quality, complex metal parts at a reasonable cost. They offer customized solutions and excellent customer service to meet the needs and requirements of their clients. Their commitment to quality and innovation is a testament to their dedication to excellence.