There are three different die casting metals that are commonly used: aluminum, magnesium, and zinc. Each of these metals has its own unique properties, which makes them ideal for different types of die casting applications. Aluminum is strong, lightweight, and corrosion-resistant, which makes it ideal for aerospace and automotive applications. Magnesium is the lightest of all the structural metals, which makes it ideal for applications where weight is a critical factor. Zinc is the easiest of all the metals to cast, which makes it ideal for applications where high-volume production is required.

Zinc die casting parts are among the most popular in the industry. Zinc is an excellent material for die casting because it has a low melting point, which means that it can be easily cast into complex shapes. Zinc is also very strong, which makes it ideal for applications where strength is a critical factor. Zinc is also very stable, which makes it ideal for applications where dimensional stability is important.

There are many companies that offer zinc die casting services, but not all of them are created equal. One company that stands out from the rest is (brand name removed) Chicago White Metal Casting, Inc. CWM. CWM is known for producing the most difficult die casting parts in aluminum, magnesium, and zinc die cast metals.

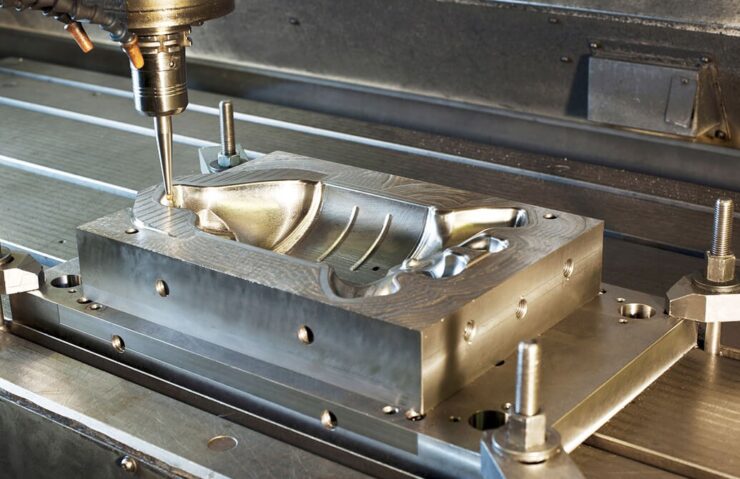

CWM has been in business for over 80 years and has been continuously improving its processes and capabilities to deliver high-quality products to its customers. The company uses state-of-the-art equipment and technology to ensure that each part is produced to the highest standards. CWM also has a team of experienced engineers and designers who work closely with customers to develop the best possible solutions for their needs.

One of the major advantages of working with CWM is the company's ability to produce complex parts with tight tolerances. CWM has a variety of die casting machines that can produce parts of different sizes and shapes with great accuracy. The company also has a robust quality control system in place to ensure that each part meets the customer's specifications.

Another advantage of working with CWM is the company's commitment to sustainability. CWM uses recycled materials in its manufacturing processes, which helps to reduce waste and conserve natural resources. The company also has a comprehensive energy management program in place to reduce its carbon footprint.

In conclusion, if you're looking for a company that can produce high-quality zinc die casting parts, look no further than CWM. With its state-of-the-art equipment, experienced team, and commitment to sustainability, CWM is the best choice for your die casting needs. Contact CWM today to learn more about its services and how it can help your business grow.